Medidor de densidad de lodos Densitómetro de líquidos en línea

- información

- Descripción del producto

- vídeo

Production Introduction

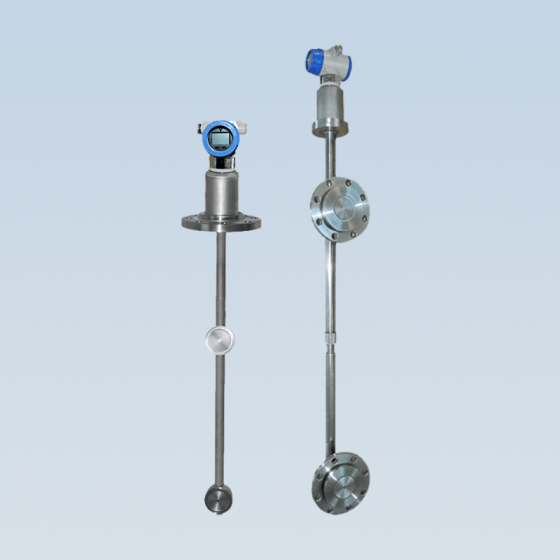

The industrial liquid density meter, mounted at the top, serves as a continuous online tool designed to gauge the density of liquids. Its primary application lies in the realm of industrial process automation and control. It produces a corresponding analog signal in the range of 4-20mA, reflecting alterations in the density of the medium. Furthermore, it can transmit a digital signal after conversion, allowing for remote calibration and monitoring purposes.

Production Features

Stainless steel wetted components, safe and reliable

It is easy to install and use, and the reading can be displayed by inserting liquid.

Simplify maintenance without regular cleaning.

Top mounted liquid densitiy meter calibration requires no standard reference source, no laboratory calibration and no process interruption.

Intrinsically safe type can be used in hazardous sites The sanitary type can be installed on the food production site.

Product Parameters

Measurement Range: | Density: 0.000 – 5.000 g/cm31 |

Accuracy: | Density 0.5–2 g/cm3 |

Resolution: | ±0.005 g/cm3 |

Calibration Method: | User performed |

Temperature Range (Sample): | 0 – 100 °C (32 – 212 °F) |

Communication: | 4 – 20 mA, HART Protocol |

Display: | Digital LCD |

Operating Environment: | Temperature: -10 – 60°C (14 – 140°F) |

Power Requirements: | 15 – 30 VDC (24 VDC recommended) |

Dimensions: | Individual dimensions vary depending on model, volumetric displacement no more than 0.15 cm3 (0.01 in3) |

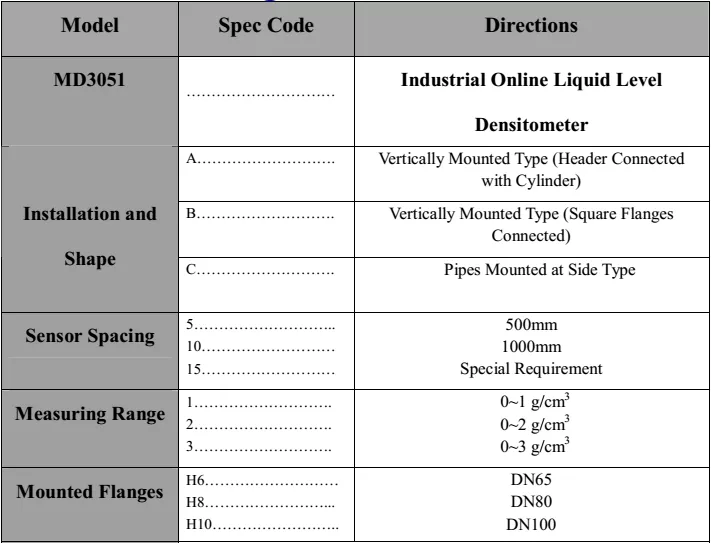

Product order sheet

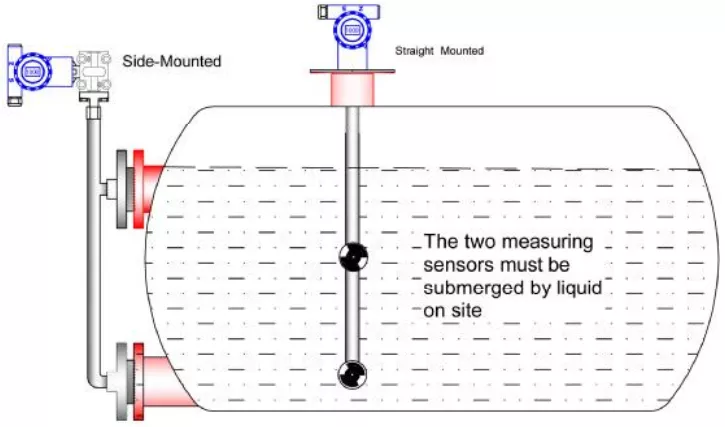

Product installation

Production line

2. La configuración en forma de campana entre el tubo de medición del densímetro de líquidos en línea y el asiento del diafragma mitiga la posibilidad de retención de medio o gas. Esta elección de diseño también protege el diafragma del impacto directo del fluido, prolongando así su vida útil operativa.

3. Cuando se trata de medios que experimentan fluctuaciones significativas de temperatura, se implementa un mecanismo de compensación de temperatura para mantener la precisión de la medición del densímetro.